Load cell sensors are reliable components But like any mechanical device, they have a finite lifespan. Understanding the signs that indicate a replacement is necessary can prevent costly downtime and ensure accurate measurements.

Common Signs of Load Cell Sensor Deterioration

- Inaccurate Readings:

- Drift: A gradual shift in the sensor’s zero point or calibration.

- Nonlinearity: Deviations from the expected linear relationship between input force and output signal.

- Hysteresis: Differences in output readings for increasing and decreasing loads.

- Physical Damage:

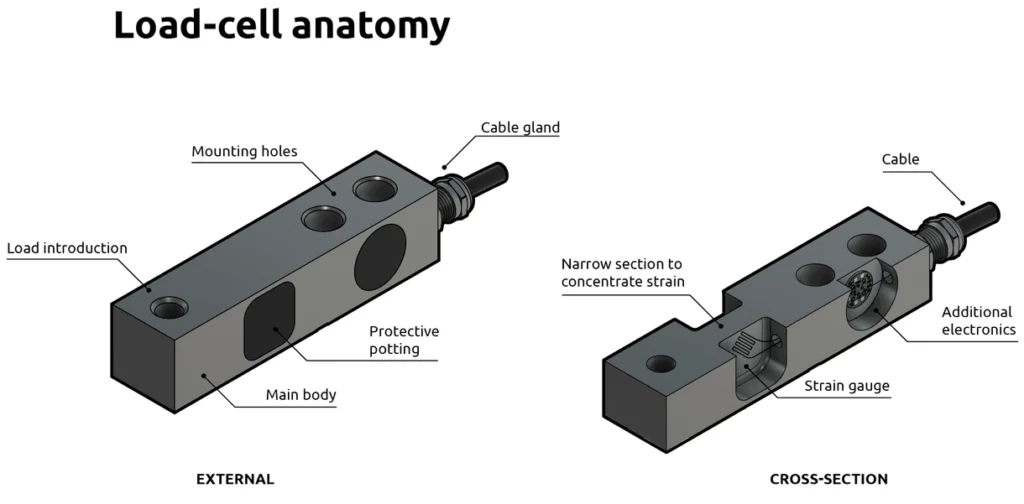

- Visible Damage: Cracks, dents, or other physical damage to the sensor’s housing or internal components.

- Corrosion: Rust or other corrosive damage, especially in harsh environments.

- Mechanical Wear: Wear and tear on the load cell’s load-bearing components.

- Electrical Issues:

- Intermittent or Erratic Readings: Inconsistent or fluctuating output signals.

- High Noise Levels: Excessive electrical noise interfering with the sensor’s signal.

- Cable Damage: Damaged or frayed cables can lead to signal degradation or complete failure.

Factors Affecting Load Cell Lifespan

Several factors can influence the lifespan of a load cell sensor:

- Operating Environment: Harsh environments with extreme temperatures, humidity, or vibration can accelerate degradation.

- Overloading: Exceeding the sensor’s rated capacity can cause permanent damage.

- Improper Installation: Incorrect installation or mounting can lead to premature failure.

- Electrical Interference: Exposure to electromagnetic interference can affect the sensor’s performance.

- Regular Maintenance: Neglecting regular calibration and cleaning can shorten the sensor’s lifespan.

When to Consider Replacement

While some issues can be addressed through calibration or repair, there are instances when replacement is the most cost-effective and reliable solution:

- Severe Physical Damage: If the sensor’s physical integrity is compromised, replacement is necessary.

- Persistent Inaccurate Readings: Despite calibration and troubleshooting, if the sensor continues to provide inaccurate measurements, replacement is recommended.

- Frequent Failures: If the sensor fails repeatedly, even after repairs, it may be more economical to replace it with a new one.

- Outdated Technology: As technology advances, older load cell sensors may become less reliable or less efficient. Upgrading to a newer model can improve performance and accuracy.

Preventive Maintenance

Regular maintenance is crucial to prolong the lifespan of load cell sensors:

- Calibration: Periodic calibration ensures accuracy and compensates for drift.

- Cleaning: Regular cleaning removes dirt and debris that can affect performance.

- Visual Inspection: Inspect the sensor for signs of damage or wear.

- Environmental Monitoring: Monitor the operating environment to identify potential issues.

By understanding the signs of deterioration and implementing preventive maintenance practices, you can maximize the lifespan of your load cell sensors and ensure reliable, accurate measurements.